Type 2 Surge Protector (SPD)Manufacturer

Type 2 spd AC Surge Protective Device

Leikexing Electric is a professional manufacturer of surge protectors, specializing in the production of high-quality surge protectors (SPD).

Leikexing Electric has 8 years of experience in the production of surge protectors, with an annual output of nearly 1 million surge protectors (SPD).

Leikexing Electric always puts customers at the center and takes product quality as the core concept, providing the highest quality products (SPD) and the most satisfactory services.

Type 2 AC Surge Protector (SPD)

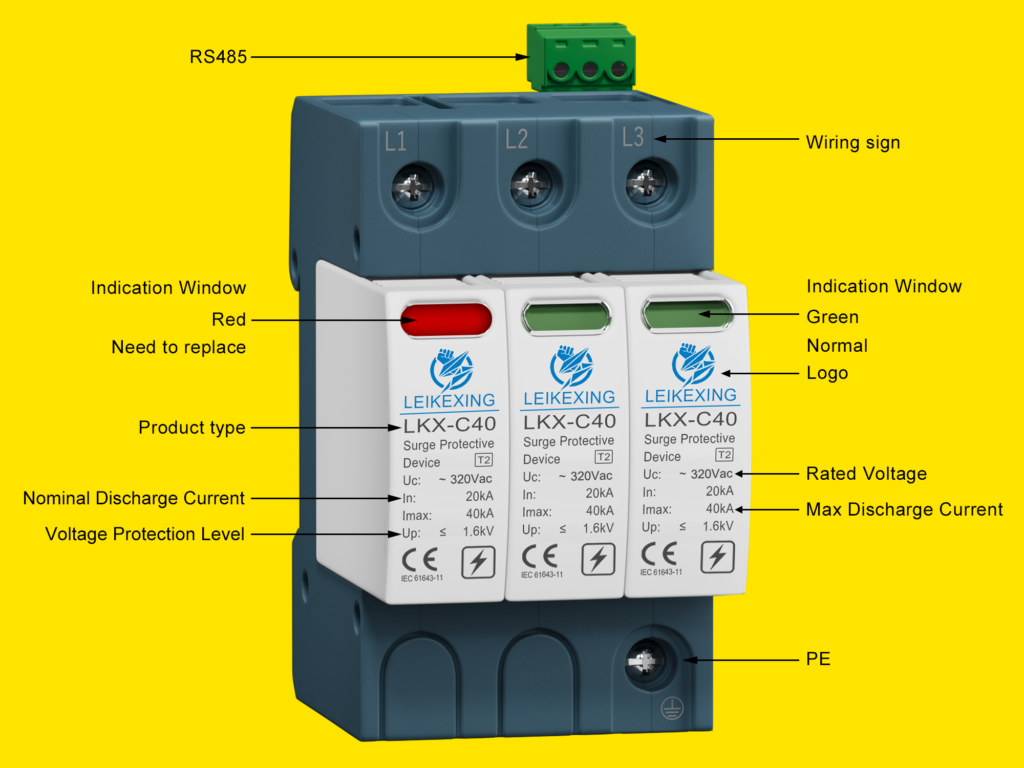

Leikexing series single-phase/three-phase type 2 spd AC power surge protector

Type 2 surge protectors are usually installed at the lightning protection boundary between LPZ1 and LPZ2 zones or beyond, such as floor distribution boxes, meter boxes, or terminal boxes. Its main purpose is to further protect critical or sensitive electrical equipment by limiting voltage to prevent transient overvoltage from causing damage to the equipment. The Type 2 surge protector should be a voltage limiting type, with a lightning current capacity of not less than 20KA. It should be installed at critical or sensitive electrical equipment to absorb more of the remaining surge and have good suppression effect on transient overvoltage.

Type 2 AC Surge Protector (SPD)

Leikexing series single-phase/three-phase type 2 spd AC power surge protector

The key parameters of Type 1 surge protector include: surge current Iimp, maximum continuous operating voltage Uc, voltage protection level Up, and response time tA. These parameters are crucial for evaluating and selecting the performance of surge protectors.

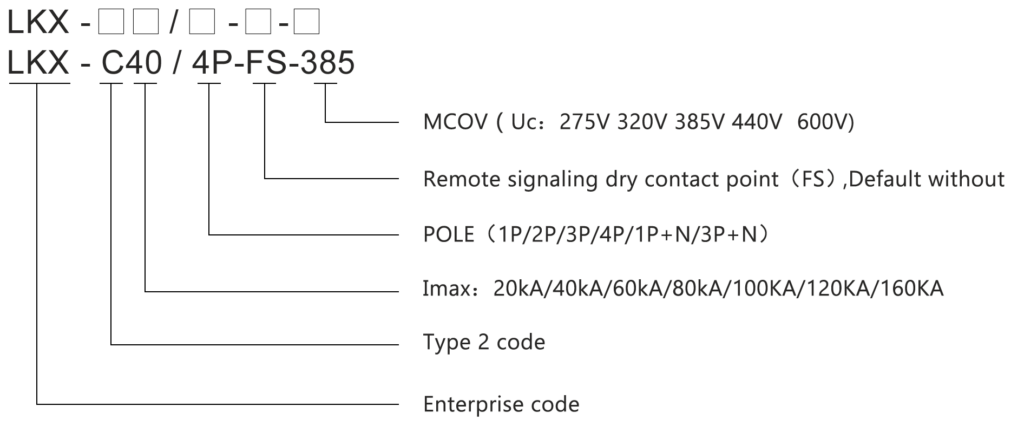

Specification parameters:

◆ Type 2/T2/Class C

◆ Nominal voltage Un: 230V 400V

◆ Max. continuous operating voltage Uc: 275V/320V/385V/440V

◆ Nominal discharge current (8/20 μs) In = 10kA 20KA 30KA 40KA 60KA 80KA Type 2

◆ Impulse discharge current (8/20 μs) Imax = 20kA 40KA 60KA 80KA 100KA 120KA Type 2

◆ Protective elements: Metal Oxide Varistor (MOV), Gas Discharge Tube (GDT)

High quality surge protector

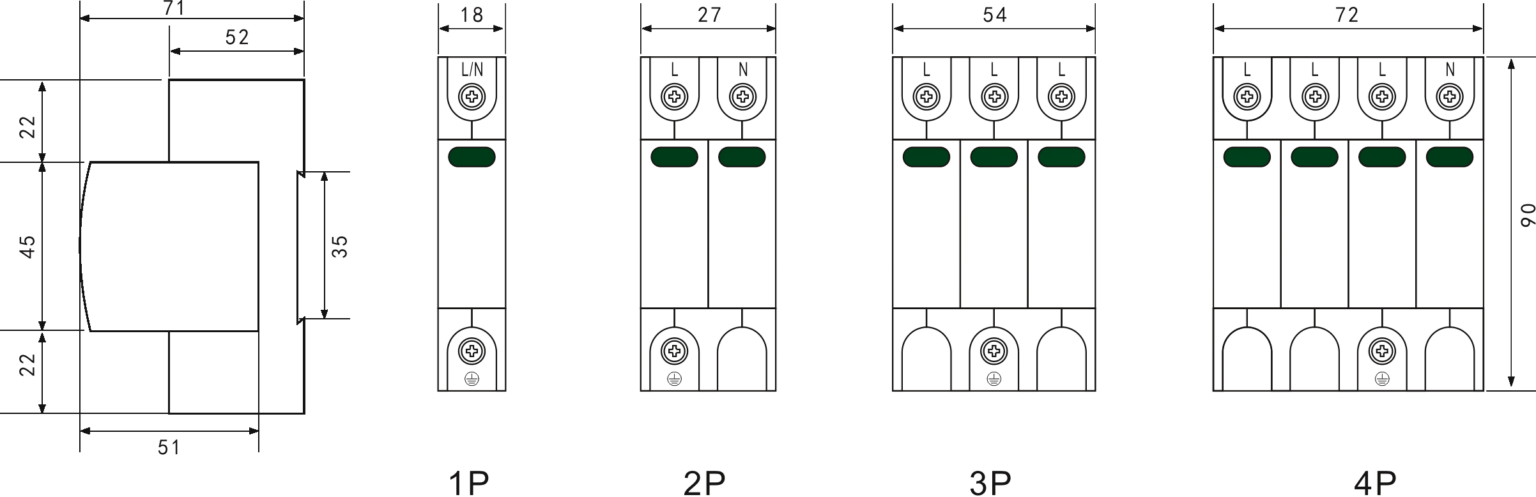

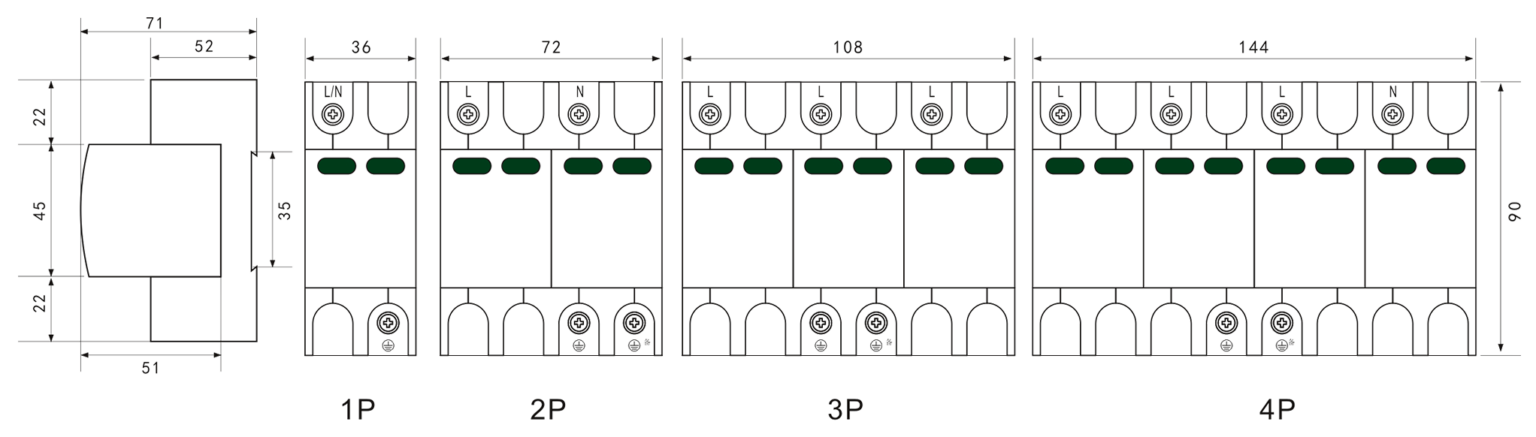

AC surge protector dimensions

Leikexing series single-phase/three-phase type 2 ac power surge protector

The function of Type 2 surge protector

Type 2 surge protector is to prevent two levels of voltage from acting on the equipment simultaneously, protecting low-voltage equipment from damage caused by surge voltage. It is usually installed on the low-voltage side of the power system and is mainly used to protect low-voltage equipment.

Installation and maintenance of type 2 surge protector

Clearly define the installation location

Type 2 surge protectors should be installed at the entrance of electrical equipment or circuits to maximize the protection of the equipment from the impact of surge voltage. When choosing the installation location, consideration should be given to the equipment’s usage environment, wiring layout, and areas that are susceptible to lightning strikes.

Preliminary preparation work

Before installation, it is necessary to ensure that the power is disconnected to avoid the risk of electric shock. At the same time, prepare the necessary tools and materials, such as screwdrivers, soldering irons, insulating tape, etc.

Specific installation steps

After installation, the working status of the surge protector should be regularly checked to ensure that it is in good condition. Once abnormalities are detected, they should be promptly addressed or replaced. In addition, it is necessary to regularly maintain the surge protector, including cleaning, fastening wiring, etc., to ensure its normal operation and extend its service life.

★ Regular inspection: including checking the appearance of the surge protector for cracks, deformation, or other physical damage, checking the integrity of the wiring parts, confirming that there is no oxidation phenomenon in the cable joints and wiring terminals, checking whether the grounding wire is firm, and confirming that the installation surface is clean and free of dust, oil stains, and other dirt.

★ Cleaning: Regularly clean the casing and wiring parts of the surge protector, wipe them with a clean, dry cloth, and gently wipe the installation surface with an eraser to remove dust, oil stains, and other dirt.

★ Replacement: When serious damage is found on the appearance of the surge protector, it needs to be replaced. Meanwhile, if the surge protector’s effectiveness in protecting the equipment deteriorates or fails, it also needs to be replaced. Generally, it is recommended to replace it after three years of use.

★ Repair: If the surge protector malfunctions, it should be immediately stopped and the cause of the malfunction should be investigated. If the cause of the malfunction is obvious, such as damage to the components, they can be replaced directly. If the cause of the malfunction is not obvious, it is necessary to contact the manufacturer for repair or replacement.